When a person walks on a standard epoxy floor, static charges can easily build up due to friction, as epoxy is an insulative material. This can lead to electrostatic discharge, which may disrupt operations or damage equipment in certain industries. ESD (Electrostatic Discharge) flooring, also called static dissipative flooring (1 MΩ to 1000 MΩ) or conductive flooring (0.025 MΩ to 1 MΩ), offers superior control by preventing static buildup from affecting individuals or sensitive equipment. An effective ESD system includes the flooring along with additional safeguards like ESD footwear, grounded work surfaces, and wrist straps.

Benefits of ESD Flooring

ESD flooring incorporates conductive elements that lower the floor’s resistance, allowing static charges to be safely directed to the ground. This approach leverages the principle that electricity follows the path of least resistance, guiding static away from surfaces. Poured-in-place polymer ESD flooring is generally more efficient than anti-static mats or tiles. Conductive materials in these floors create a seamless path from the floor’s surface to the grounding layer, ensuring effective static dissipation. Key benefits include:An toàn cho nhân sự: Bảo vệ người lao động khỏi sốc điện hoặc nguy cơ nổ, đặc biệt trong môi trường phòng sạch.

- Personnel Safety: Protects workers from potential shock or explosion, especially in cleanroom environments.

- Equipment Protection: Shields sensitive electronic components from harmful static, which is crucial in electronics manufacturing.

- Enhanced Durability: Outperforms tiles, which may detach in demanding conditions.

- Cost Savings: Reduces the need for repairs or replacements of electronic devices damaged by static discharge.

- Comprehensive Static Control: Creates a fully controlled environment when used with ESD-compliant footwear and accessories.

Recommended Industries

Controlling static electricity is essential across various industries. In electronics manufacturing, for instance, anti-static floors protect delicate components such as circuit boards and microchips, where even 250 volts of static can cause damage. Humans typically notice static discharge at 2,500 volts, making ESD floors critical in protecting both equipment and personnel. Production facilities handling pills, sugars, grains, or munitions also rely on ESD floors to prevent static buildup that could trigger explosions, as airborne particles can become combustible. In these industries, an arc of static electricity can cause ignition and lead to catastrophic incidents.

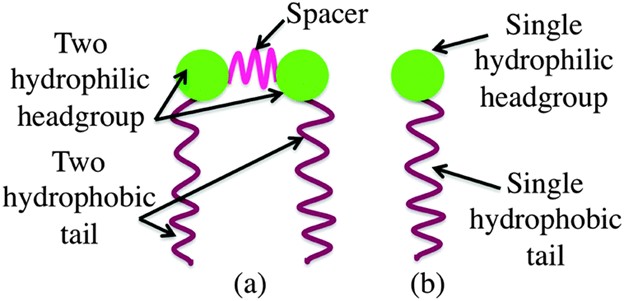

How Anti-Static Flooring Works

ESD flooring channels any accumulated static from the surface to the ground. Example resistance requirements:

- Dissipative Range: 10⁶–10⁹ Ω

- Conductive Range: 2.5×10⁴–10⁶ Ω (based on ASTM F150 standards)

Certain ESD floors may also have an added topcoat to improve durability.

How anti-static flooring works

Any accumulated electrical charges should be conducted from the surface to ground.

Requirements example

Surface-to-ground resistance:

- dissipative range: 106–109 Ω

- conductive range: 2.5⋅104–106 Ω

According to ASTM F150. Some flooring systems can also include an additional thin topcoat.

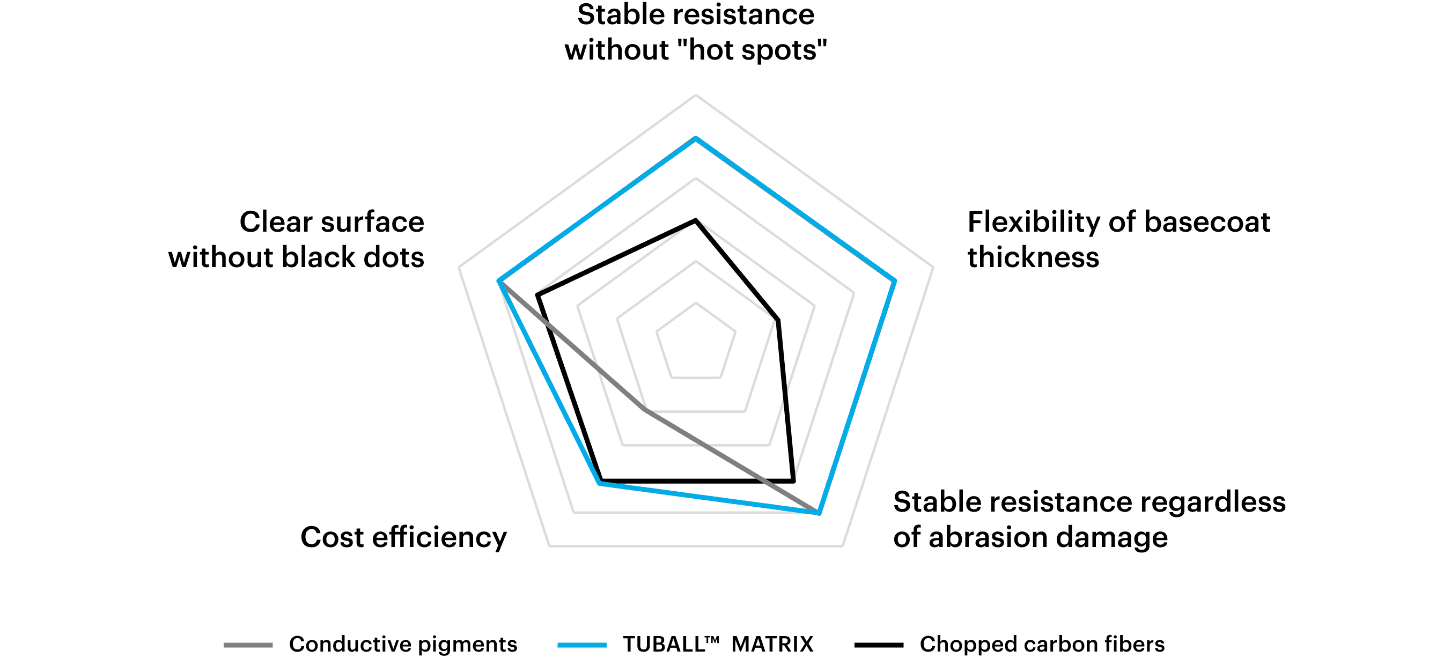

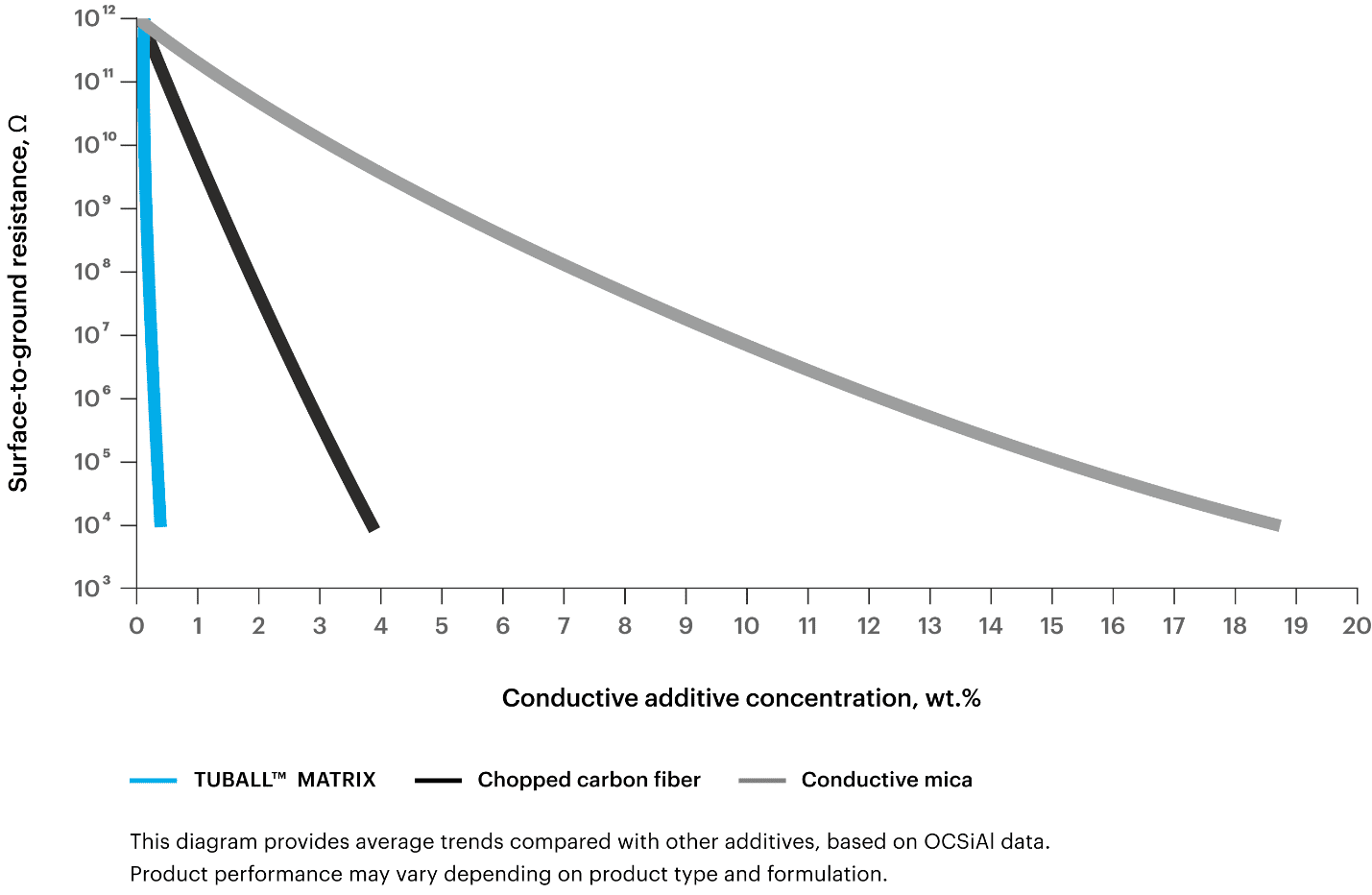

TUBALL™ graphene nanotubes are a versatile conductive agent offering strong performance on all key parameters

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

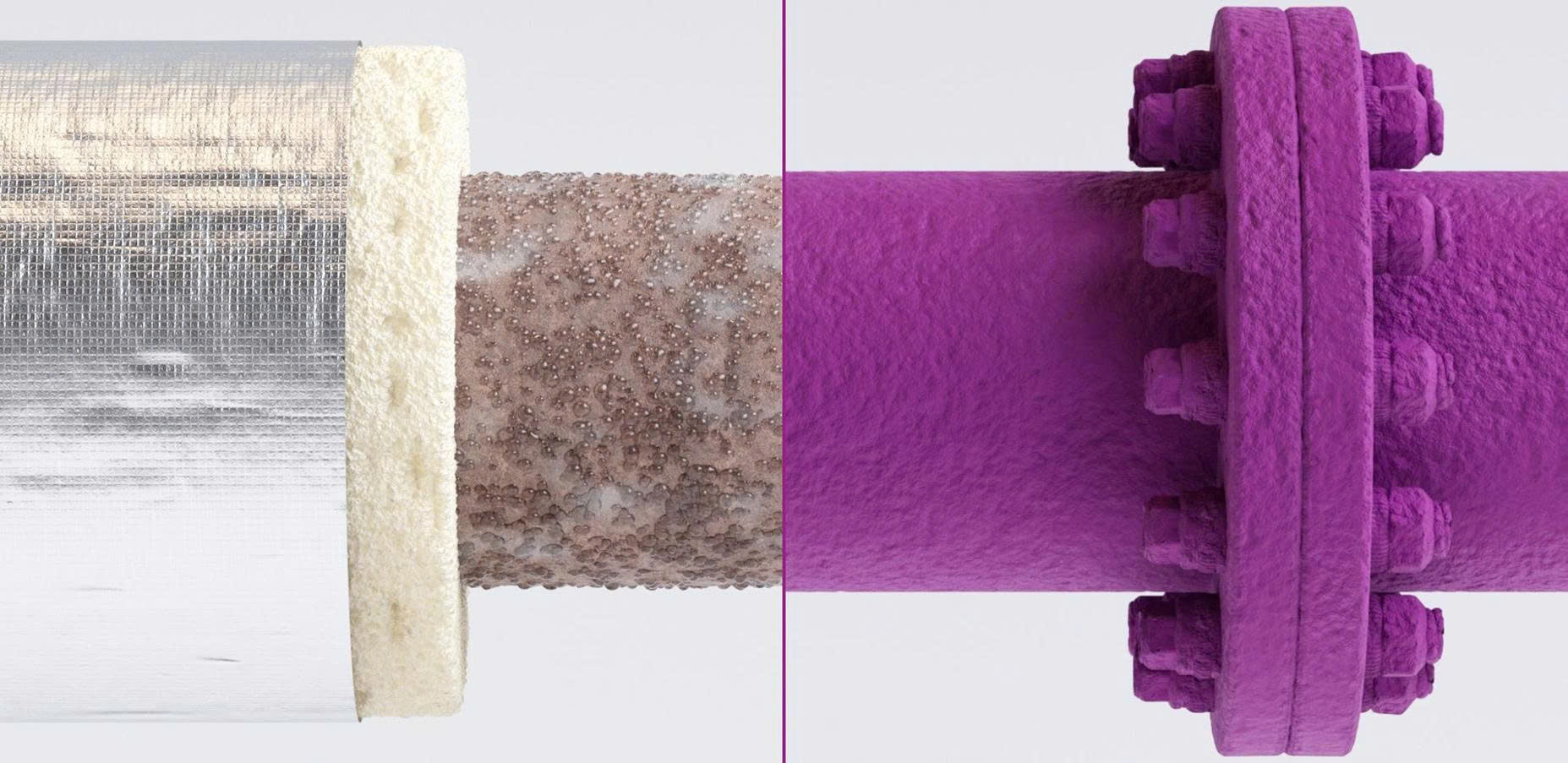

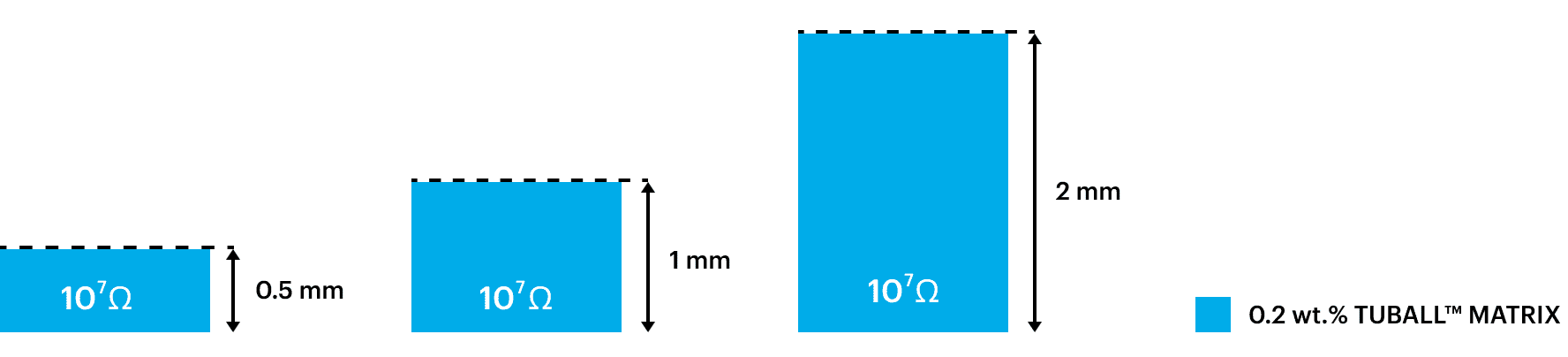

Low working dosages and flexibility in basecoat thickness

Compared with chopped carbon fiber and conductive mica, TUBALL™ nanotubes allow the required conductivity to be obtained at much lower working dosages.

Surface-to-ground resistance at different base coat thickness

Because of the length of chopped carbon fiber (2 mm or longer), the thickness of the base layer must be at least as much (~2 mm). This can result in difficulties in the installation process, increased costs, and the possibility of there being insulating “hot spots”. In contrast, TUBALL™ can be used with various anti-static flooring systems and thicknesses.

Conductive mica has the highest price per property, which is a result of the initial high price of this ESD additive combined with the high working dosage required, which is ~ 5–20 wt.%.

Product performance may vary depending on product type and formulation.

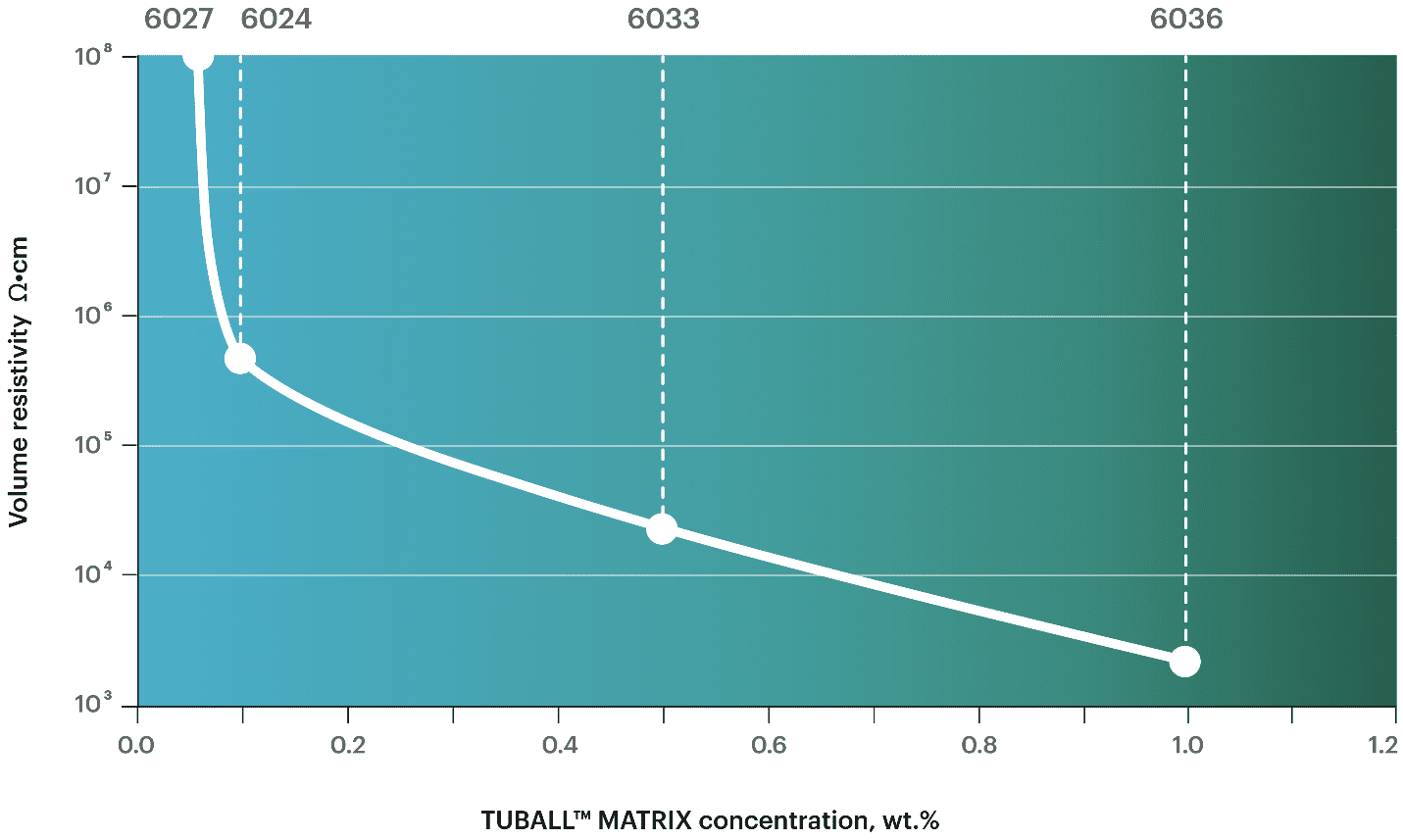

Full range of electrical resistivity while preserving color

Results for epoxy resin D.E.R. 351.

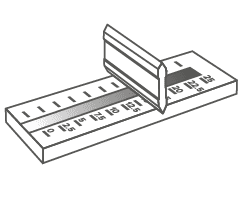

Easy to apply

TUBALL™ MATRIX can be processed with standard equipment that is widely used in the coatings industry

Standard single-shaft high-speed mixer

25 min total dilution time

Instant quality control with a grindometer to reach particle size ≤ 15 µm

Other benefits provided by TUBALL™ nanotubes for static dissipative flooring:

- Floors with TUBALL™ nanotubes can be used without conductive primer

- Low dosage gives greater flexibility in the final formulation

- Easy to apply and the low dosage makes the logistics less complex and more efficient

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™-based products.

Mercury Chemical is the official distributor of OCSiAl in Vietnam, contact us to get the solution for ESD flooring.