Carbon atoms form various allotropes with distinct physical properties, including graphite, diamond, fullerenes, nanotubes, and graphene. The latter three are primarily synthetic. Each allotrope’s origin, structure, and production method influence its effectiveness as an additive, with graphene and nanotubes offering the most advantageous properties.

| Single-walled carbon nanotubes (SWCNTs), also called graphene nanotubes (GNTs) | Graphene | Multi-walled carbon nanotubes (MWCNTs) | Nanographite structures (incl. few-layer “graphene”, graphene flakes (graphene nanoplatelets), graphene oxide (GO), reduced graphene oxide (RGO) and others) | Graphite structures (incl. carbon black) |

|  |  |  |  |

| A graphene layer seamlessly rolled into a tube | A single sheet or monolayer of carbon atoms tightly bound in a hexagonal honeycomb lattice | A concentric arrangement of SWCNTs, i.e. multiple layers of graphene seamlessly rolled into a concentric tubular structure | Graphene flakes are small platelets of graphite; GO/RGOare few-layer nanoscale graphites, have oxygen groups or have undergone additional reduction | A large set of multiple graphene sheets |

| Industrial-scale production (hundreds of tonnes) | Not designed as an additive to materials (production in kgs) | Industrial-scale production (thousands of tonnes) | Industrial-scale production (thousands of tonnes) | Industrial-scale production (millions of tonnes) |

These carbon-based additives, with the exception of graphene, are produced at a scale of hundreds or thousands of tonnes and are available for industrial applications.

Carbon nanotubes

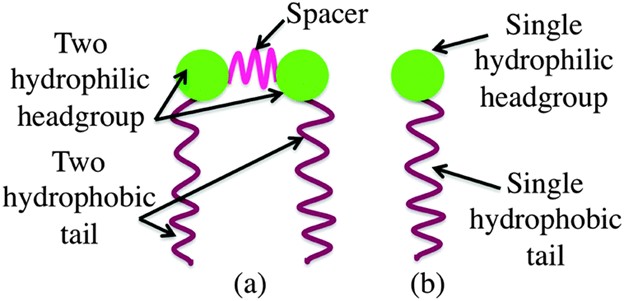

Carbon nanotubes are categorized into two main types: single-walled (SWCNTs) and multi-walled (MWCNTs). Although similar, their structural differences lead to distinct physical properties. SWCNTs consist of a single graphene layer rolled into a hollow cylinder, which is why they’re often called graphene nanotubes (GNTs). In contrast, MWCNTs are formed by multiple layers of graphene concentrically rolled into a tube.

These differences between single-walled and multi-walled carbon nanotubes result in substantially different properties and corresponding impacts on materials after their introduction.

Physical parameters of SWCNTs vs MWCNTs

| Parameter | SWCNTs | MWCNTs |

| Key parameters | ||

| Typical diameter | 1–2 nm* | 7–100 nm |

| Typical length | Up to 1 mm** | Up to 1 mm |

| Aspect ratio | Up to 10 000 | 50–4000 |

| Mechanical properties | ||

| Elastic modulus | 1000–3000 GPa | 300–1000 GPa |

| Tensile strength | 50–100 GPa | 10–50 GPa |

| Electronic structure properties | ||

| Thermal conductivity at 300K | 3000–6000 W/(m·K) | 2000–3000 W/(m·K) |

| Minimum working dosage as an anti-static additive | 0.01% | 0.5% |

* Larger diameters are possible but could lead to an increased number of defects

** Longer lengths are possible but only at laboratory-scale

Single-walled carbon nanotube applications

SWCNTs show remarkable potential as multifunctional additives, enhancing conductivity, anti-static properties, strength, flexibility, and adhesion in various materials. These enhancements can often be achieved with very low SWCNT concentrations (tenths or hundredths of a percent), allowing existing manufacturing processes to remain largely unchanged. Applications of SWCNTs can be classified by industry, material, or product type, with major consumption seen in composite materials, reinforced plastics, industrial coatings, car tires, and materials for power sources. Adhesives, lubricants, anti-static plastics, conductive films, and cables represent a secondary tier, while niche applications use smaller quantities of SWCNTs.

SWCNT markets with the greatest potential

Composite materials with single-walled carbon nanotubes

SWCNTs are increasingly used in alternative energy, infrastructure, and automotive and aircraft industries, focusing on applications that demand lightweight, strong materials with enhanced physical properties, such as wind turbine blades, boat hulls, and aircraft parts. The use of SWCNTs to reinforce composite materials and improve their strength is steadily growing in these sectors2, 3.

Reinforced plastics with SWCNTs

Driven by automotive and aerospace needs for weight reduction and durability under extreme conditions, SWCNTs enhance strength and reduce fuel or battery demands.

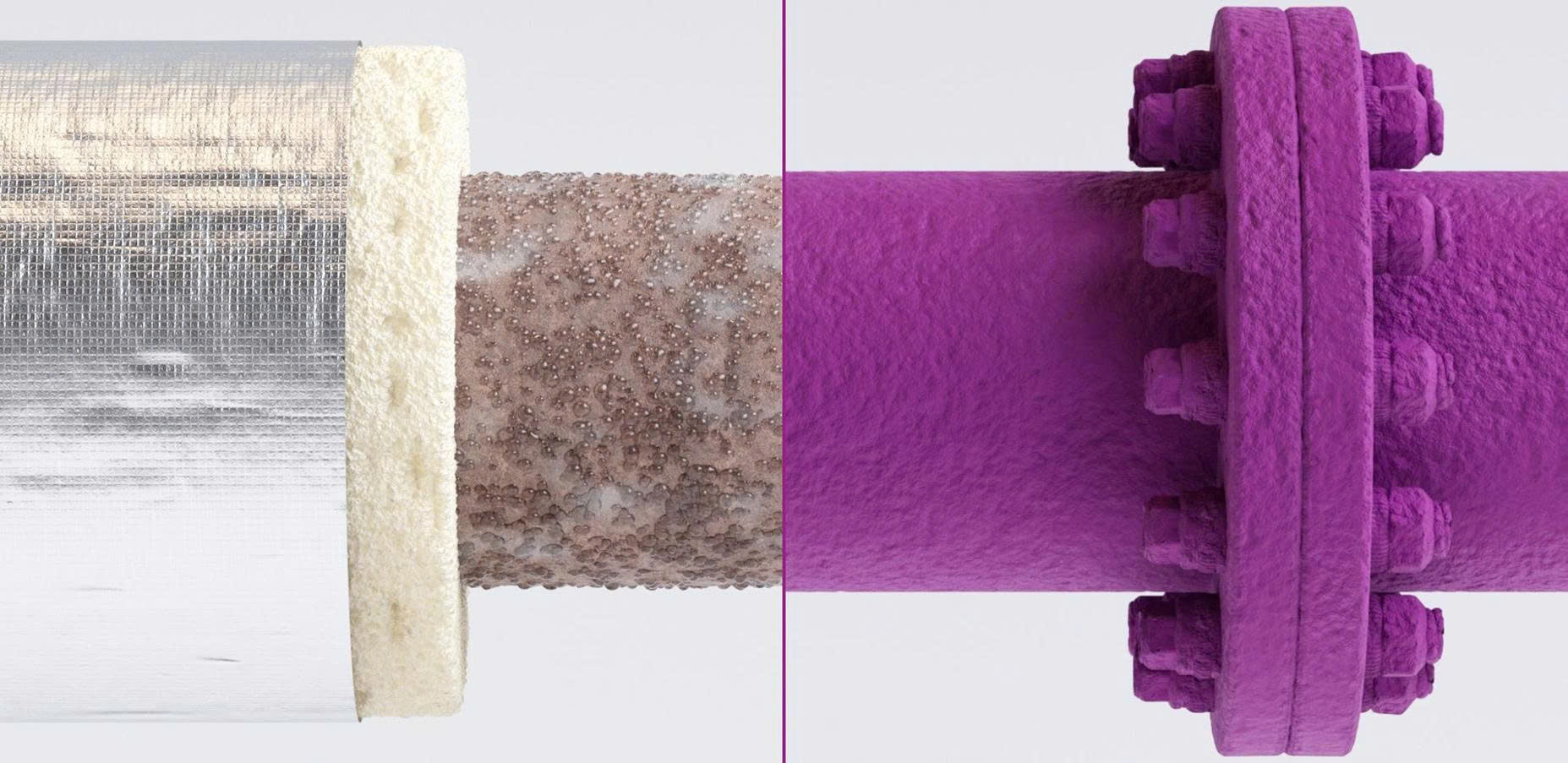

SWCNTs in industrial coatings

As multifunctional additives, SWCNTs improve vehicle and equipment coatings, anti-static floors, and storage containers, with potential applications in over half of industrial coatings products.

Single-walled carbon nanotubes in car tires

SWCNTs improve tire stiffness, tear resistance, fuel efficiency, and grip. They provide conductivity without needing additional fillers, with high applicability in premium and standard tire segments.

Electrochemical power sources with SWCNTs

SWCNTs enhance rechargeable power sources, especially lithium-ion batteries, by increasing storage density and longevity in applications like electric vehicles, laptops, and mobile phones.

SWCNTs in rubber technical goods

SWCNTs boost the strength, elasticity, abrasion resistance, and durability of rubber and silicone products, with a potential use in one-third of rubber-based goods.

Structural materials containing single-walled carbon nanotubes

In materials like bitumen, asphalt, and metal composites, SWCNTs enable control over structural features and enhance performance qualities.

SWCNT markets with smaller potential

SWCNT technologies for environmental protection

SWCNTs are being developed for hazardous gas and toxin detection, as well as gas and liquid filtration systems, with future potential to penetrate 3–5% of these products.

SWCNTs in biotechnology and medicine

Due to compatibility with biomolecules, SWCNTs show promise in biosensors, medical implants, and targeted drug delivery systems.

Electronics and microelectronics with SWCNTs

The elasticity and electronic properties of SWCNTs support applications in smart textiles, transistors, RFID chips, data storage, integrated circuits, and CMOS batteries.

Overall, SWCNTs have the potential to impact up to 70% of existing materials, representing a $3 trillion market. Increased production and lower costs are expected to expand their use across diverse industrial technologies.

Source: https://tuball.com/articles/single-walled-carbon-nanotubes