Antistatic Chemical Graphene nanotubes

General information

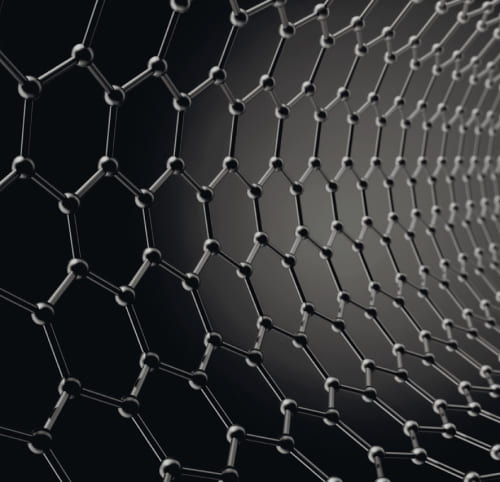

Discovered by Japanese scientists in 1991 with a 1-molecule thick layer of graphene rolled into a tube, an outer diameter of 1.5 nanometers, and a thickness of 1 angstrom. Graphene, the wonder material, Nobel Prize 2010

- GOOD CONDUCTIVE MATERIALS

One of the best conductive materials in the world

- 100 TIMES STRONGER THAN STEEL

Among the group of the hardest materials ever discovered by humans

- ULTRA LOW DOSAGE

Does not cause any chemical reaction with any other component in the compound

TUBALL™ Graphene nanotubes

TUBALL™ is a product line of single-walled carbon nanotubes (SWCNT), also known as graphene nanotubes (GNT), that can be applied in various industries. TUBALL™ graphene nanotubes create a 3D network that helps materials improve electrical conductivity, enhance mechanical properties, and many other features.

| Specifications | Unit of measurement | Value | Evaluation method |

|---|---|---|---|

| Graphene nanotubes (GNT) content* | wt.% | ≥ 80 | OCSiAl internal method: ash residue |

| GNT average outside diameter | nm | 1,6 ± 0,4 | Optical absorption: ISO/TS 10868:2017 (E) |

| Length of GNT | μm | >5 | AFM(E) |

| Specific surface area | m2/g | ≥ 300 | BET METHOD: ISO 9277:2010 (E) |

| G/D ratio | unit | ≥ 40 | Raman (532 nm): NIST Special Publication 960-19 |

| Metal impurities* | wt.% | ≤ 15 | OCSiAl internal method: ICP-AES |

| Moisture content | wt.% | < 5 | OCSiAl internal method based on ISO 712:2009 |

| Reference products | Liquid antistatic agent | Carbon black | Conductive mica | TUBALL™ MATRIX |

|---|---|---|---|---|

| Dosage, wt.% | 0.2–4.0 | 4–12 | >15–20 | 0.1-1.0 (0.01–0.1 TUBALL™ nanotubes) |

| Resistivity level, Ω/sq | 108-1011 | 103-1011 | 103-1011 | 103-1011 |

| Physical effects | Mild effect | Heavy impact | Little impact | Little impact |

| Effect on rheology | No effect | Heavy impact | Little impact | Little impact |

| Color | Color mixing possible | Cannot | Color mixing possible | Color mixing possible |

| Dust formation during production | No dust | Dusty | No dust | No dust |

| Resistivity changes with humidity | Affected | Not affected | Not affected | Not affected |

| Resistivity stability over time | Unstable | Stable | Stable | Stable |

| Expense | $ | $/ $$ | $$$ | $$ |

TUBALL™ BATT

TUBALL™ FOR ENERGY STORAGE

TUBALL™ BATT is a solution designed for easy integration of TUBALL™ Graphene Nanotubes into electrode formulations during battery production.

TUBALL™ BATT provides a complete or partial replacement for carbon black in battery electrodes and can replace a few percent of carbon black with just 0.03–0.1% TUBALL™ Graphene Nanotubes.

TUBALL™ Graphene Nanotubes create 3D conductive networks between active material particles at very low concentrations. These nanotubes reinforce the electrode structure and improve its mechanical stability during charge/discharge. TUBALL™ enhances adhesion by establishing strong bonds between particles, reducing the amount of binder needed.

TUBALL™ MATRIX 600-x

TUBALL™ MATRIX PRODUCT LINE FOR RUBBER

The TUBALL™ MATRIX 600-x product line consists of pre-dispersed graphene nanotubes designed to provide the necessary electrical conductivity properties for rubber and significantly enhance their mechanical properties.

TUBALL™ LATEX

TUBALL™ FOR ELASTICITIES

TUBALL™ LATEX is a compound of graphene nanotubes dispersed in water for the production of latex gloves and latex products with antistatic properties, while still maintaining mechanical properties and minimal impact on the material. TUBALL™ LATEX helps achieve permanent conductivity that is independent of humidity, fully complying with the most stringent applications, including the new European standard EN 16350:2014 (EN 1149) regarding antistatic properties in protective equipment.

TUBALL™ MATRIX 200 / 300-x

TUBALL™ FOR COMPOSITES AND COATINGS

TUBALL™ MATRIX 200 / 300-x are pre-dispersed graphene nanotube compounds designed to provide uniform, long-lasting electrical conductivity for various materials: epoxy, polyurethane, polyester, etc. TUBALL™ MATRIX is compatible with many different shades while still meeting ESD standards.

TUBALL™ MATRIX 800-X SERIES

TUBALL™ FOR THERMOPLASTICS

TUBALL™ MATRIX 800-x are pre-dispersed graphene nanotube compounds specifically designed to provide superior electrical conductivity for thermoplastic materials while maintaining mechanical properties and having minimal impact on the materials.

The TUBALL™ MATRIX 800 line is designed for the most demanding applications in the automotive, petrochemical, oil and gas, medical, pharmaceutical, and electronics industries.

TUBALL™ COAT_E

TUBALL™ FOR COMPOSITES AND COATINGS

TUBALL™ COAT_E is an easy-to-use water-dispersible graphene nanotubes compound that provides long-lasting antistatic properties to water-based paints and coatings without significantly affecting their color and mechanical properties.

TUBALL™ COAT_E is suitable for the production of antistatic water-based paints and coatings for the following applications:

- UV coatings

- Packaging for electronics