Powder coatings have a tendency to agglomerate at a certain temperature, which is mainly due to the softening of the resin, leveling agent, and other materials that make up the powder coatings when exposed to heat. Powder coatings are all thermosetting powder coatings, that is, the resin as the main film-forming material is an organic polymer with a low molecular weight. These resins have a physical property. At a lower temperature, it appears as a hard and brittle glass state. When the temperature rises to a certain level, the resin begins to transform into a state with certain elasticity and adhesion, which is lower than this. Temperature, the resin returns to the non-adhesive glass state, and the temperature at which the glass state and viscoelastic state of the resin change is called the glass transition temperature of the resin.

Different resins have different glass transition temperatures. For example, the glass transition temperature of epoxy resin and polyester resin is about 50 degrees Celsius, the glass transition temperature of gloss enhancer (701) is about 30 degrees Celsius, and the glass of liquid leveling agent The degree of change is at minus Celsius. The greater the amount of material with a low glass transition temperature in the powder coating formulation, the lower the glass transition temperature of the system. Determining the glass transition temperature requires special large-scale instruments. The general powder coating manufacturers do not have such expensive instruments and equipment. In the production process, they cannot grasp the glass transition temperature of the powder system in time. Therefore, the powder system is used during production. The glass transition temperature is about 40 degrees Celsius, and this temperature is set as the safe temperature for powder coating agglomeration. Then in production (and in the process of product storage and transportation), use this as a standard, and relevant personnel should strengthen the sampling inspection of product agglomeration when it is near and above this temperature. At present, it has entered the summer production stage. The increase in temperature will make it easier for powder coating products to agglomerate. How to prevent powder coatings from agglomerating in the work?

First, we must establish a concept: it is a natural law for powder coatings to agglomerate at a certain temperature. To prevent the agglomeration of powder coatings, the powder coating products must be below their glass transition temperature during the entire process of powder coating production such as grinding, packaging, storage, and transportation.

According to this view, there are the following solutions:

In the production of polyester resin, select some alcohol or acid that can increase its glass transition temperature, or reduce the amount of alcohol that can lower the glass transition temperature of the resin to increase the glass transition temperature of the polyester resin.

Reduce the use of low glass transition temperature polymers in the design of powder coating formulations, such as leveling agents and gloss enhancers, to ensure that the glass transition temperature of the powder coating system does not decrease.

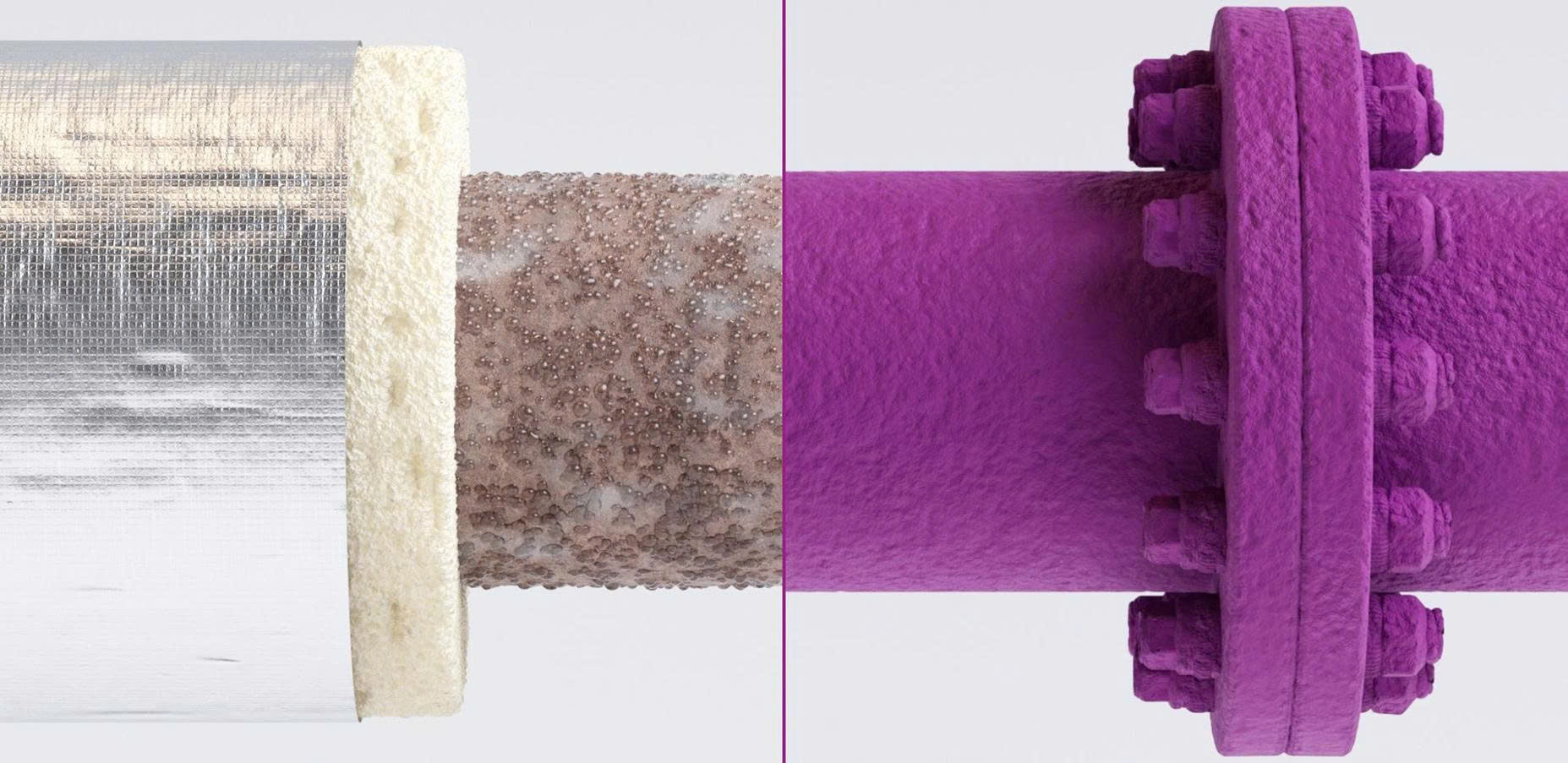

In terms of production, the broken pieces of the steel strip should be fully cooled before entering the grinding process. When grinding, the feed speed should be appropriately reduced, the amount of induced wind should be increased, and the imported air should be equipped with a cold air conditioner to control the grinding temperature. However, if the crushed flakes cannot be cooled before grinding, the latter method will not play a good role. Consider the method of forced cooling of the broken flakes for low temperature treatment, which is more effective than adding air conditioners.

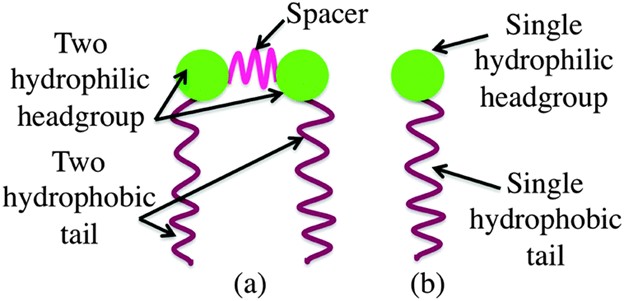

In addition, anti-caking aids, such as Hydrophobic fumed silica AEROSIL® R 972 or pure Aluminum Oxide AEROXIDE® Alu C. Anti-caking agents are generally used at the same time as broken tablets the grinding effect is the best.

Thermoplastic powder coatings: Thermoplastic powder coatings include: polyethylene, polypropylene, polyester, polyvinyl chloride, chlorinated polyether, polyamide, cellulose, polyester. Examples are PVC powder coatings, polyethylene powder coatings, nylon powder coatings, fluororesin powder coatings, latex powder coatings, etc.

AEROXIDE® Alu C is a fine-particulate, pure aluminium oxide (Al2O3) with high specific surface area and marked aggregate and agglomerate structure. Because of it high purity and low water content, the product can be used well as an additive to anorganic materials, for heat insulation, and also as a catalyst substrate. The positive surface charge can be used to control the electrostatic charge., can be added to prevent adhesion between powder particles

Using any single method can not effectively prevent the agglomeration of powder coatings, and excessive use of one method will bring other disadvantages to powder coatings. A variety of methods can be used to scientifically coordinate to effectively prevent agglomeration of powder coatings.

For further consultation on preventing agglomeration in powder coatings, feel free to reach out to us.