Gemini Surfactant – An Advanced Solution for High-Performance Coatings, Adhesives & Latex Rubber Applications

News

29/07/2025

- Overview of Gemini Surfactants

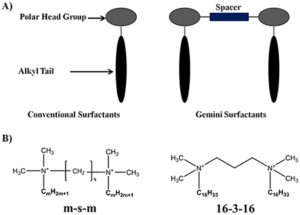

Surfactants have long played a fundamental role in industrial formulations such as paints, adhesives, waterborne polymers, and emulsion systems. With the advancement of chemical engineering, a new generation of surfactants has emerged: Gemini surfactants – representing a leap in performance and molecular design.

Unlike conventional surfactants which possess a single hydrophilic head and hydrophobic tail, Gemini surfactants consist of two hydrophilic groups, two hydrophobic groups, and a molecular spacer. This twin-tail, twin-head configuration enables superior surface activity, pigment dispersion, ionic compatibility, and long-term stability in harsh environments.

Evonik (Germany), a global leader in specialty chemicals, is one of the pioneers in developing high-performance Gemini surfactants tailored for coatings, adhesives, emulsion polymers, and other technical applications.

- Mechanism of Action

Gemini surfactants operate on the classical surfactant principle: they form micelles, reduce surface/interfacial tension, and stabilize multiphase systems. However, their dual molecular structure offers enhanced capabilities:

- Superior wetting and pigment dispersion: Enables better distribution and coverage with reduced dosage.

- Extremely low CMC (Critical Micelle Concentration): 10 to 100 times lower than conventional surfactants, ensuring effective performance at minimal concentrations.

- Improved emulsion and latex stability: Essential for long-term storage and durability in adhesives and polymer dispersions.

- High tolerance to salts, temperature, and pH: Suitable for demanding industrial environments.

- Excellent compatibility with waterborne systems: Does not compromise polymer properties.

- Industrial Applications of Gemini Surfactants

3.1. Applications in Industrial & High-Performance Coatings

Industrial coatings demand high adhesion, coverage, color stability, and process reliability. Gemini surfactants enhance:

- Pigment wetting and dispersion: Optimize gloss and coverage while maintaining viscosity control.

- Stability in waterborne paints: Enhance storage stability and long-term performance.

- Foam control and surface leveling: Prevent film defects like pinholes and craters.

Evonik Products:

- TEGO® Wet 270 / 280: Gemini-based wetting agents for difficult substrates such as metal, plastic, and glass.

- TEGO® Dispers 685: VOC-free dispersing agent offering color consistency and environmental compliance.

3.2. Applications in Emulsion Polymers & Waterborne Latex

Waterborne latexes (e.g., polyvinyl acetate, styrene-butadiene, acrylics) are used in coatings, adhesives, coated fabrics, and gloves. Gemini surfactants contribute to:

- Efficient emulsification during polymerization: Achieves uniform particle size and improved dispersion.

- Enhanced bonding and film properties: Ideal for thin-film latexes requiring elasticity and strength.

- Reduced coagulation during synthesis

Evonik Products:

- TEGO® Addid 700 Series: Tailored Gemini surfactants for acrylic and polyurethane emulsions.

- TEGO® Wet and Dispers series: Improve particle control and thermal stability.

3.3. Applications in Latex Gloves & Technical Rubber Materials

In manufacturing nitrile and natural rubber gloves or engineered elastomers, Gemini surfactants serve to:

- Improve latex dispersion in dipping baths: Prevent agglomeration and ensure homogeneity.

- Enhance film uniformity and mechanical strength

- Facilitate mold release (demolding)

- Ensure layer compatibility in dipping, coating, and curing processes

3.4. Applications in Waterborne Adhesives

Adhesives require dispersion stability and bonding reliability across diverse surfaces. Gemini surfactants help to:

- Stabilize emulsion-based polymer systems: e.g., acrylics, PU, EVA.

- Enhance initial and long-term adhesion

- Improve substrate wetting and spreadability on metals, wood, and plastics

Evonik Gemini surfactants can be synergistically used with silica systems and rheology modifiers to optimize adhesives for automotive, construction, and furniture applications.

- Comparative Performance Table

| Performance Criteria | Nonionic Surfactants | Anionic Surfactants | Gemini Surfactants |

| Critical Micelle Concentration | Moderate | Moderate | Very Low |

| Pigment Dispersion | Moderate | High | Excellent |

| Emulsion Stability | Good | Moderate | Outstanding |

| Complex Polymer System Handling | Limited | Limited | High |

| Hard Water Compatibility | Low to Moderate | Low | Very High |

| Cost/Performance Ratio | Good | Good | Optimal with added value |

- Featured Gemini Surfactants from Evonik – Distributed by Mercury Chemical

| Product Name | Key Features | Main Applications |

| TEGO® Wet 280 | Wetting of low-energy surfaces | Waterborne coatings, technical paints |

| TEGO® Dispers 685 | VOC-free pigment dispersant | Protective coatings, engineering plastics |

| TEGO® Addid 760 | Enhances latex dispersion during polymerization | Emulsion polymers, synthetic latex |

| TEGO® Twin 4000 | High-performance, low-foam Gemini nonionic | Water-based adhesives, hybrid systems |

| TEGO® Surten E-Series | Anti-agglomeration, enhances binder strength | Latex gloves, technical rubber |

- Conclusion: A Sustainable and Efficient Solution for Industrial Materials

Gemini surfactants are not just an innovation but a practical technology platform for industries demanding high performance, robust stability, and optimized material costs.

As the official distribution partner of Evonik in Vietnam, Mercury Chemical is committed to delivering high-quality Gemini surfactants, comprehensive technical solutions, and customized formulation support for all relevant industrial applications.