Thermoplastic Powder Coating (Nylon 11)

Rilsan® Fine Powders

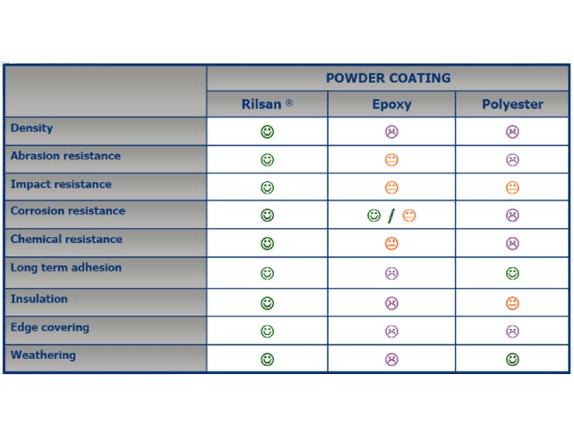

Rilsan® Fine Powders is a ready-to-use powder coating product made from polyamide 11, a type of polymer that is 100% bio-based. This high-performance polymer is derived from the castor bean plant, a renewable resource that does not compete with human or animal food sources. Rilsan® Fine Powders provides excellent protection for metal surfaces due to its superior chemical and mechanical properties compared to thermoset plastic-based products (Polyester and Epoxy). Additionally, Rilsan® Fine Powders can also be used as a primary material (3D printing) as well as an additive in various applications (coatings).

Characteristics of Rilsan® Fine Powders compared to thermoset plastic-based powder coatings:

Application

- Automotive & Transport: Rilsan® Fine Powders provides exceptional abrasion resistance and oil resistance

- Electronics & Batteries: superior electrical insulation (high voltage & ultra-high voltage) and offers outstanding flexibility, impact and abrasion resistance, corrosion resistance, and UV protection for a wide range of battery components.

- Exterior: Corrosion resistance properties and a variety of colors allow for extensive outdoor use.

- Oil & Gas Pipelines & Water Treatment: corrosion resistance, flexibility, and impact, abrasion, and chemical resistance.

- Medical: extremely durable and provides excellent protection for applications in the medical field (smooth & warm to the touch, easy to clean, chemical resistant, sterilizable, high durability & lightweight, and corrosion resistant).

- Heavy Industry: Superior abrasion resistance, smooth surface, and excellent hardness, Rilsan® Fine Powders are widely used in mining, textiles, and food industries.

- Energy: protective coating for wind turbine bearings, turbines, blades.

- Clothing: Rilsan® Fine Powders MC with a small particle size of 50 um is used to coat clothing components (underwear, swimwear)

- Mesh Products: Rilsan® Fine Powders T designed for the dipping process is the optimal coating solution for metal mesh items.

- Construction & Electrical Industry: protective coating for electrical boxes, anti-loosening of screws.

Additives for electrostatic powder coating production

A diverse list of chemical raw materials helps enhance the quality and aesthetics of electrostatic powder coatings to meet the stringent demands of all applications. Additionally, it provides chemical solutions that improve the preservation and adaptability of electrostatic powder coatings (free-flow & anti-caking agents), which are particularly essential and suitable for the hot and humid environment in Vietnam. Many products utilizing proprietary and advanced technology will assist electrostatic powder coating manufacturers in improving product quality and addressing issues in production and storage.

- Adhesion promoters: TEGO® Addbond series

- Gloss / Hardness Enhancement: TEGO® Variplus AP

- Matting / Anti-scratching agents: SPHERILEX® DP-0111 /0112 / 0115

- Free-flow / Anti-caking agents: AEROXIDE® Alu C, AEROSIL® 200 / R972 / E972 và TEGO® Powder Aid

- Pigment wetting / Dispersing / Degassing agent: TEGO® Powder Aid D01