Overview of Marine and Protective Coatings

The marine paint and industrial paint industry in Vietnam is developing strongly, following the trend of modernization and environmental friendliness. Current international regulations promote the use of water-based paints and paints that do not contain volatile organic compounds (VOCs) to minimize environmental impact. Nano technology and graphene materials are being widely applied to improve corrosion resistance and increase the lifespan of paints. In particular, the application of new generation materials significantly reduces VOC emissions while providing long-lasting protection. These advanced solutions not only enhance product quality and reduce negative environmental impacts but also strictly comply with international standards. This helps businesses in the industry enhance their competitiveness and ensure safety for maritime works and vehicles.

MATERIALS AND SOLUTIONS FOR MARINE PAINTING AND PROTECTIVE COATINGS

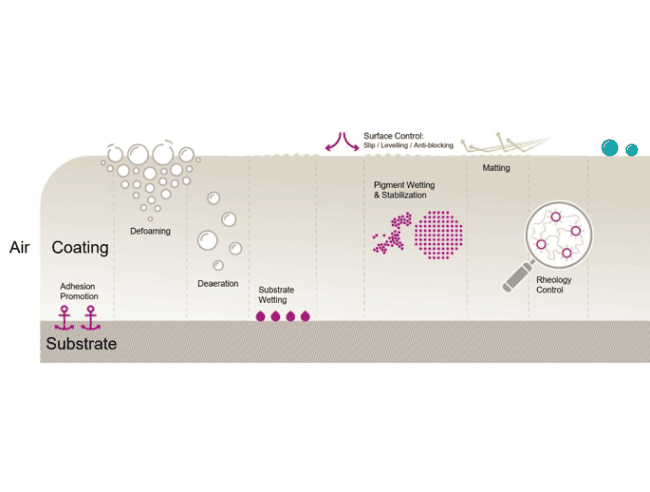

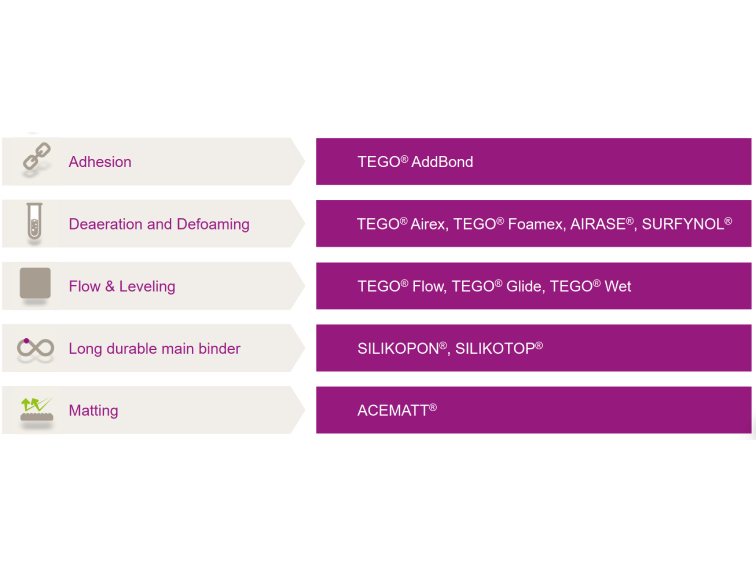

Evonik’s range of additives for protective and marine coatings provides an optimal solution for safeguarding metal and concrete structures from harmful impacts such as corrosion, fire, and harsh environmental conditions, especially in marine environments.

Evonik offers additives for both waterborne and solventborne coating systems, tailored for applications on marine vessels, offshore platforms, yachts, and container ships. Evonik’s waterborne coating additives not only deliver high environmental performance with low VOC levels but also ensure safety for users and ecosystems. For demanding applications, Evonik’s solventborne additives provide strong and durable protection.

KEY PRODUCTS

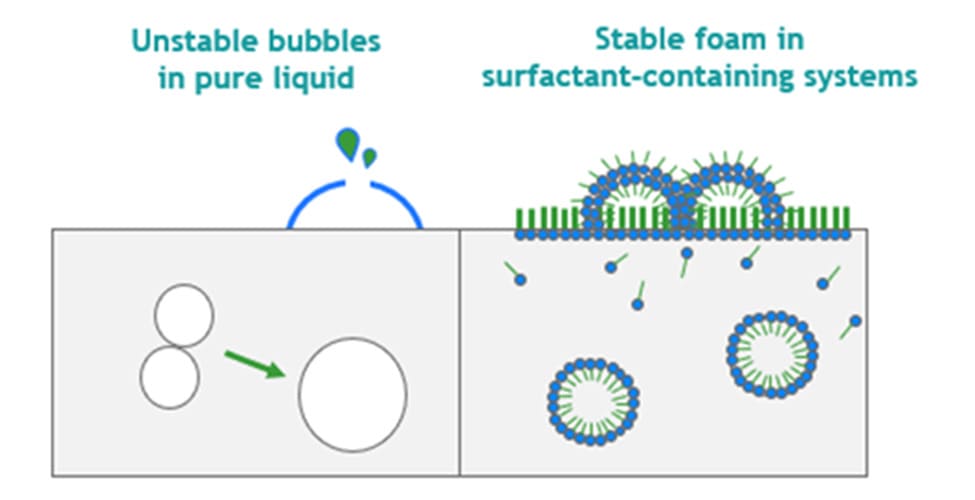

With a diverse range of high-quality products such as TEGO®, ACEMATT®, AEROSIL®, SURFYNOL®, Evonik provides comprehensive solutions that optimize the production process of marine coatings and protection in Vietnam. From traditional issues such as defoaming, degassing, and dispersion to high-end requirements for matting, rheology adjustment, and heat resistance, Evonik’s products meet all these needs.

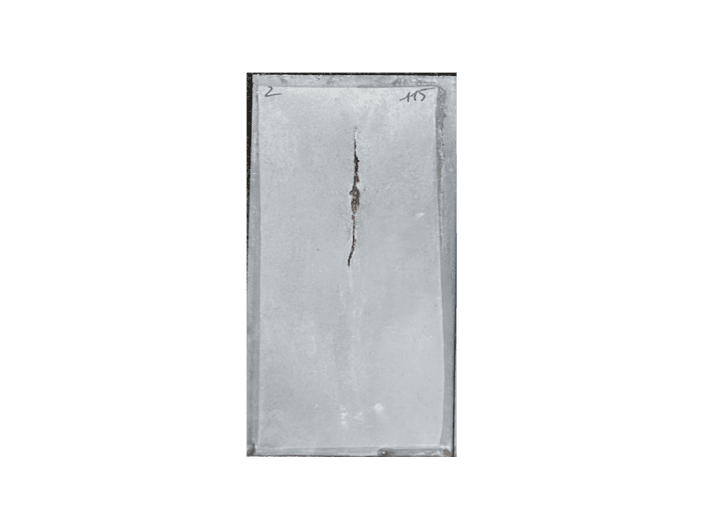

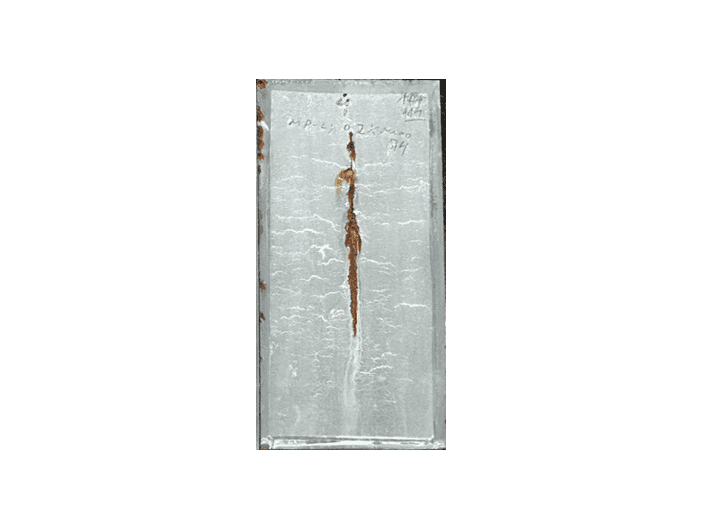

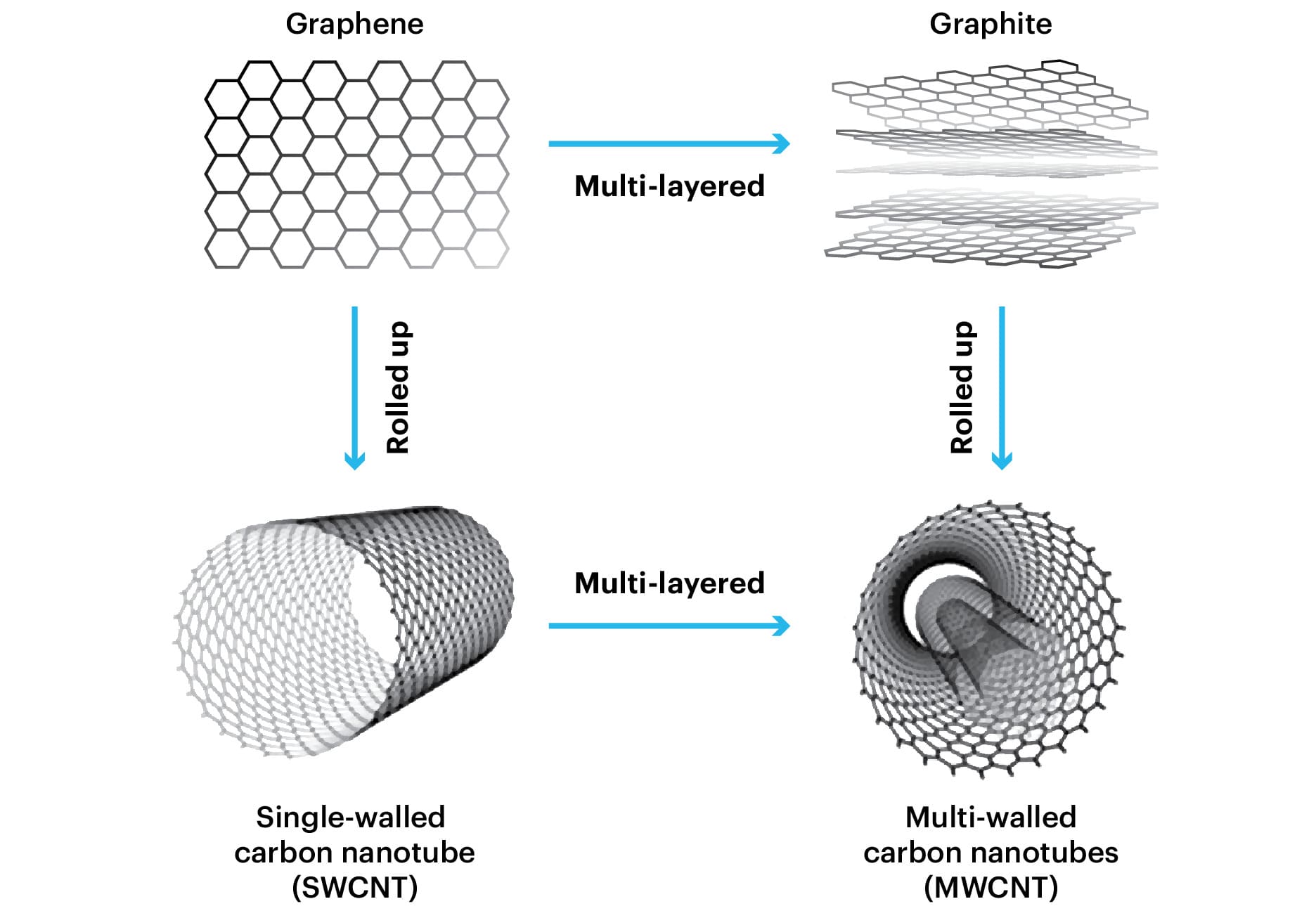

ZINC-RICH PAINTS USING GRAPHENE NANOTUBE

The application of Graphene Nanotube in zinc-rich anti-corrosion paint has brought significant improvements to the new generation of zinc-rich paints. These paints have superior corrosion resistance, meeting high standards such as C5M-ISO 12944, while significantly reducing the amount of zinc used compared to traditional paints. OCSiAl’s TUBALL™ product has been tested and proven effective by leading domestic and international paint manufacturers.