Materials for Anti-Static Floor Coatings

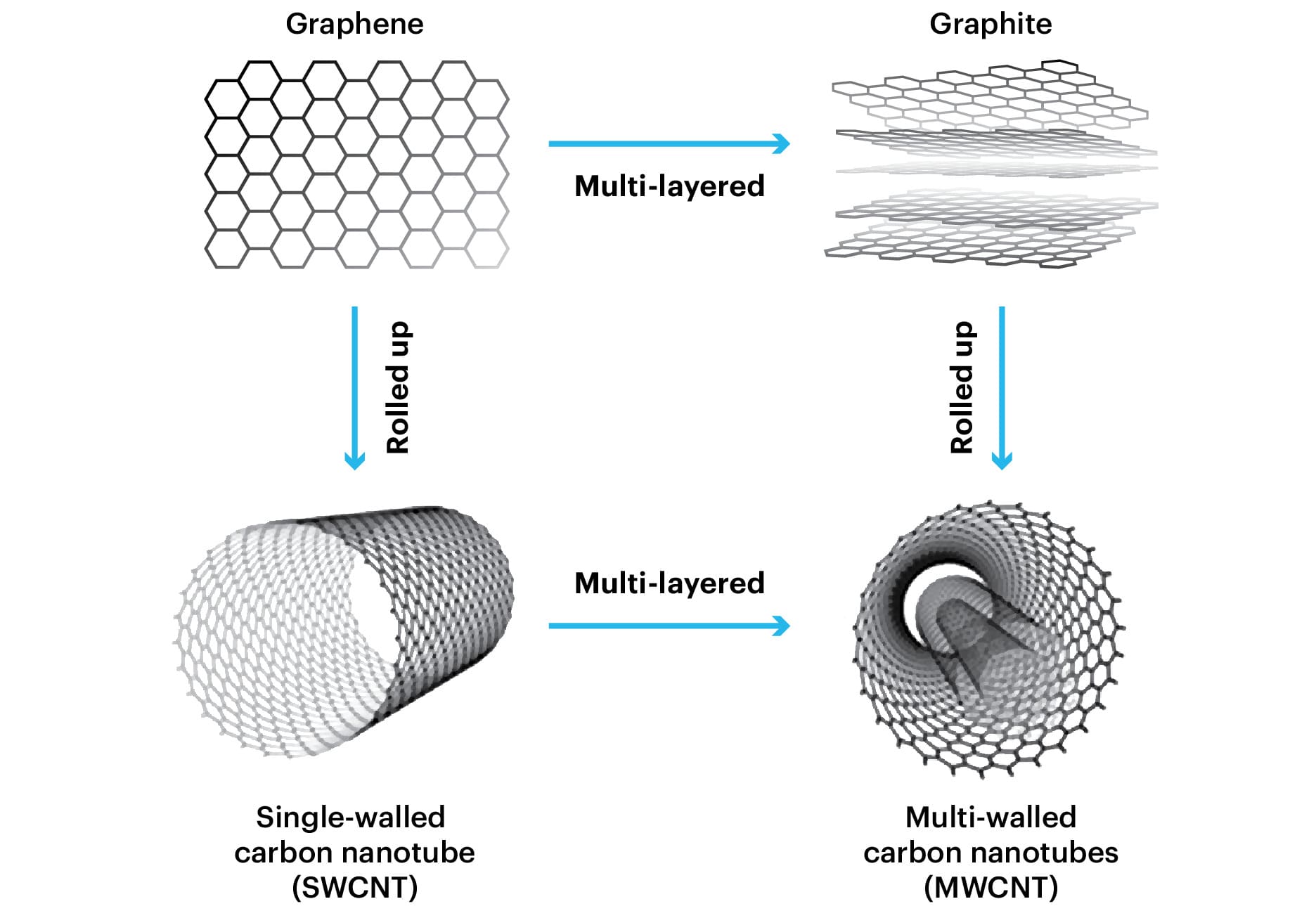

Electrostatic protection is an extremely important factor in factories producing electronic components and warehouses storing flammable materials to ensure safety and fire prevention. In Vietnam, electrostatic protection flooring systems have become increasingly popular in the construction industry. Advanced electrostatic protection additives using new materials such as Graphene Nanotube not only enhance electrostatic protection performance but also meet many stringent standards of electronic manufacturing plants and warehouses storing flammable materials, ensuring safety and optimal efficiency for all production activities.

GRAPHENE NANOTUBES APPLICATION: OUTSTANDING ADVANTAGES FOR ANTI-STATIC FLOORING

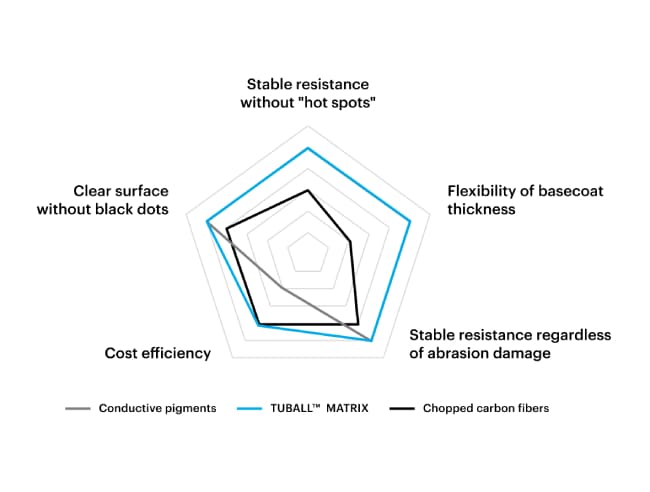

The application solution of graphene nanotube anti-static additives offers significant advantages over the use of carbon fibers for anti-static flooring.

Optimal electrical conductivity: Achieves the required conductivity with a low dosage (0.1 wt.% ~ 0.3 wt.%).

Flexible paint layer thickness: Usable with various thicknesses without increasing costs.

Preservation of aesthetics: Minimal impact on the color and surface of the floor (Reduces the occurrence of surface defects).

Long-lasting time: Maintains anti-static capability throughout the floor’s lifecycle.

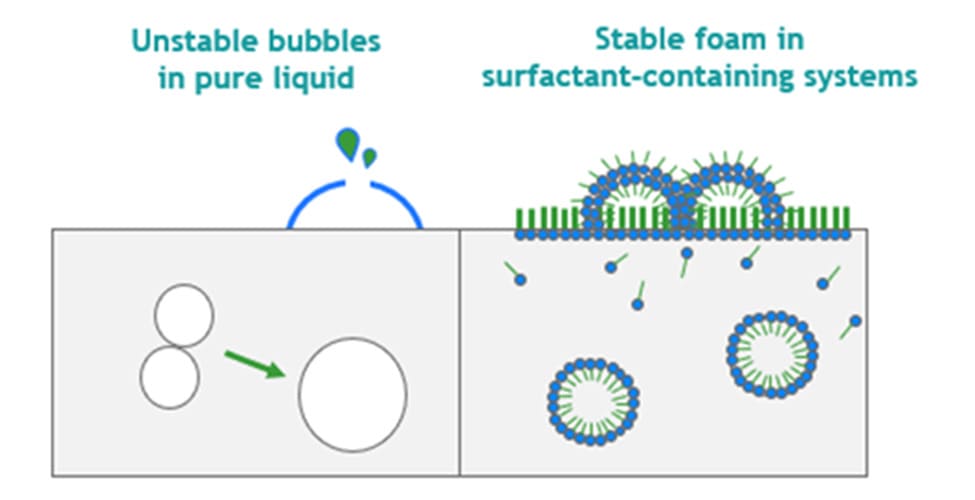

Easy to apply: Processed with standard equipment, saving time and costs.

Flexibility in formulation: Low dosage and easy to adjust the formula.

KEY PRODUCTS

The OCSiAl Group is the largest manufacturer of Graphene Nanotubes in the world. With the Tuball Matrix product, it provides a complete solution for anti-static additive lines for floor coatings, as well as technical support from Mercury Chemical to help customers meet the stringent requirements for anti-static flooring.