A defoamer is an additive that eliminates foam when making, applying, or storing paint and coatings. Foam is a difficult problem for formulators that can cause unsightly defects and expensive manufacturing processes. Defects can impact surface appearance, gloss, and adhesion. Entrained air can contribute to foam formation that negatively impacts efficiency in applications like industrial operations.

Modified polydimethylsiloxane (PDMS) and non-silicone solutions from Evonik act as foam control agents for coatings. They help prevent the formation of foam or eliminate existing foam during the production and application of coatings.

Why Are Defoamers Important?

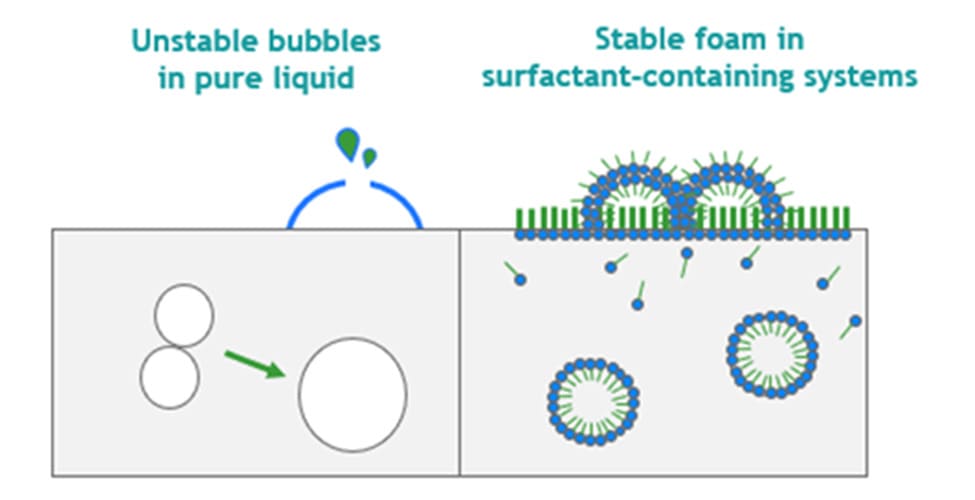

Foam Formation in Liquids

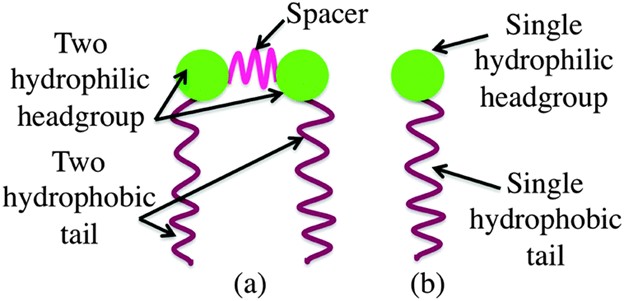

Foam forms from entrapped gas in a liquid or solid medium. Macrofoam forms at the surface of a coating while microfoam consists of small air bubbles entrapped within a coating. When a liquid is pure, such as pure water or any liquid without surfactants, it does not generate foam. However, paints are not pure liquids as they contain surface-active substances.

Foam generation is more stable in surfactant-containing systems like coatings

Causes of Foam Formation in Coatings

Many essential processes throughout the formulation of a coating can result in foam generation. Defoamers for coatings can help avoid foam-related defects caused by the following processes:

- In the production phase, the grinding or milling of pigments as well as filling paint into cans may cause foaming.

- During the application phase, foam can form when spraying, brushing, or rolling paint onto a substrate.

- Challenging substrates like wood or concrete can also contribute to foam formation.

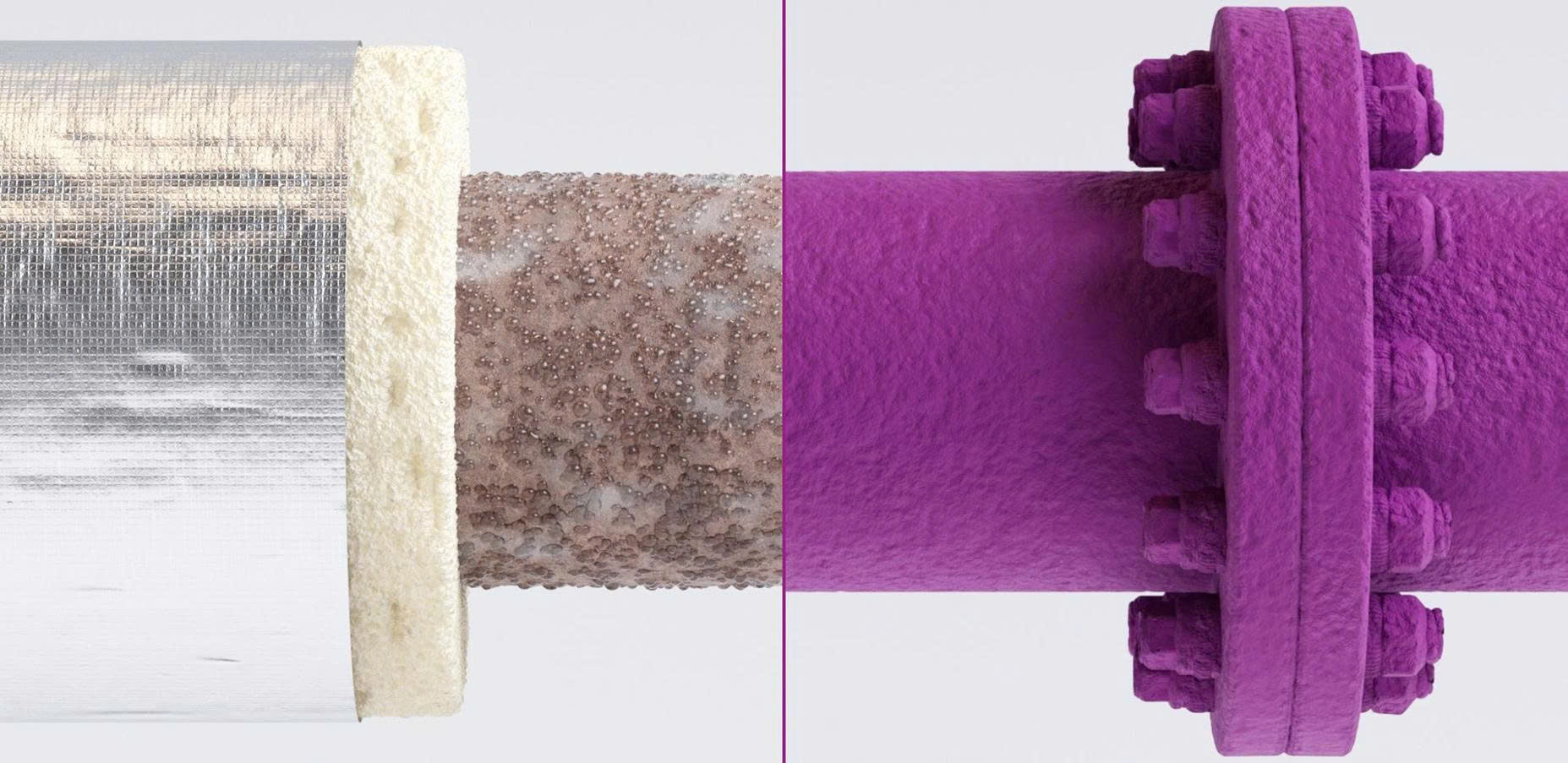

Foaming can occur at any time and cause less-than-ideal results. Uneven surfaces, reduced gloss, and poor adhesion between the coating and a surface can all result from foam formation. Pinholes, craters, and poor leveling are a few examples of foam-related surface defects.

Defoaming agents work to reduce surface tension in coatings, making foam unstable. This causes the bubble wall in a coating to thin out and eventually burst, releasing air. As a result, foam-related defects are prevented.

The mechanism of foam bubble destruction with foam control paint additives

How to Select and Evaluate Defoamers

Selecting the right foam prevention additive requires considering a coating’s criteria and conducting tests.

Selecting Defoamers

Finding the best defoaming additive first involves making note of the content within a formulation.

Type of System

Certain defoamers will work better in solventborne formulations and others will work better in waterborne formulations. Some may work well in both.

Stage of Production

Understanding the stage of production in which foam-related defects occur also helps narrow down selections. Manufacturers create some additives for the mill base stage, some for the letdown stage, and some for use in various stages.

Resin System

Only certain defoamers will be compatible with the resin used in a coating formulation. Options are available for a wide range of resins, including alkyd, acrylic, epoxy, and polyurethane.

Formulation

Whether or not a coating is high gloss, semi-gloss, matte, or high solids can all have an effect. Determining if a formulation is silicone-free or already contains a defoamer is also important. The fillers used in a coating are also essential to consider.

Application

Foam generation can occur during the brushing, rolling, or spraying of a coating on a substrate. Knowing under which application method foam typically forms in a coating is important.

Current Issues

The particular issues taking place in a coating will have a strong impact on the type of defoamer to select.

Types of Defoamers for Paint

Additive manufacturers typically offer mineral oil, silicone-based (PDMS), and silicone-free foam prevention solutions.

Mineral Oil

Mineral oil solutions are popular cost-effective additives that may contain wax or silica to boost performance.

Examples include: Surfynol 118, Tergo Foamex 2, Tego Foamex 9

Silicone-Based (PDMS)

Silicone-based (or PDMS) defoamers provide excellent long-term defoaming efficiency, broader application, and lower surface tension. They have good chemical inertness and thermal stability and have no impact on gloss or color acceptance.

Examples include: Tego Airex 900, Tego Foamex 840, Tego Airex 944

Silicone-Free

Silicone-free additives contain polymers with very low surface tension. They are easy to incorporate, result in defect-free films, and do not cause color-related issues. These solutions are also low in VOCs and are efficient for use at low surface levels.

Examples include: Tego Airex 923, Tego Airex 922, Tego Airex 910

A comprehensive foam control offering includes a range of custom defoaming solutions and foam control products to meet the needs of various industries. Evonik’s defoamer selection guide helps narrow down options by specific formulation criteria.